Delving into the synthesis of alum lab answers, this comprehensive guide provides a captivating exploration of the chemical process involved in creating this versatile compound. From its industrial applications to its environmental impact, this narrative unveils the fascinating world of alum synthesis, offering a blend of scientific knowledge and practical insights.

As we embark on this journey, we will delve into the step-by-step procedure for synthesizing alum in a laboratory setting, examining the properties of this compound before and after synthesis. We will uncover the diverse applications of alum in industries and households, including its crucial role as a water treatment agent and its presence in the food and beverage sector.

Synthesis of Alum: Synthesis Of Alum Lab Answers

Alum, also known as potassium aluminum sulfate, is a versatile compound with various industrial and household applications. Synthesizing alum in a laboratory setting is a straightforward process that involves a series of chemical reactions.

The synthesis of alum begins with the reaction between aluminum metal and sulfuric acid. This reaction produces aluminum sulfate, which is then combined with potassium sulfate to form alum.

The synthesis of alum lab answers can be a bit tricky, but it’s definitely doable. If you’re having trouble, check out this helpful guide: a fire hydrant sits 72 feet . It has step-by-step instructions and troubleshooting tips. Once you’ve got the hang of it, you’ll be able to synthesize alum like a pro!

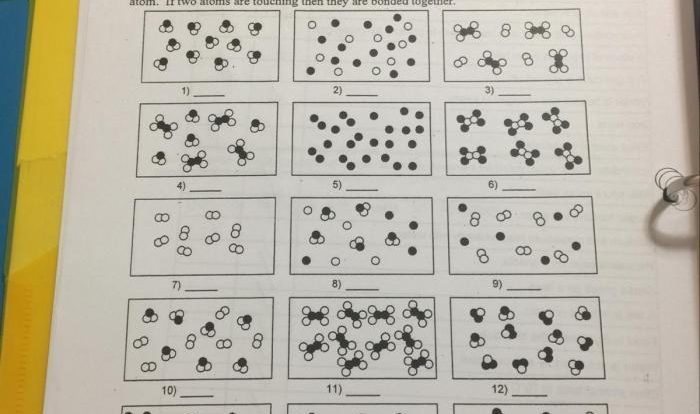

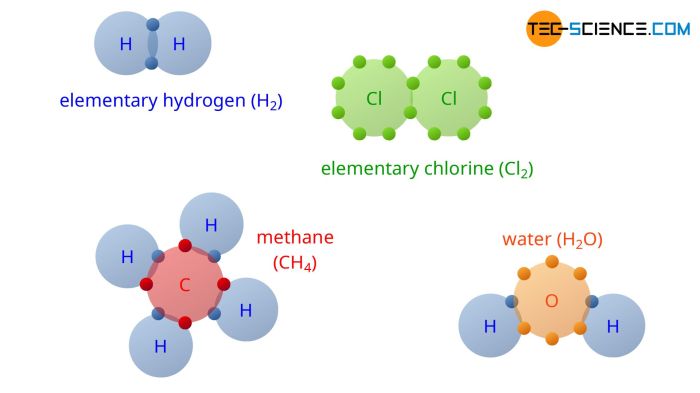

Chemical Process

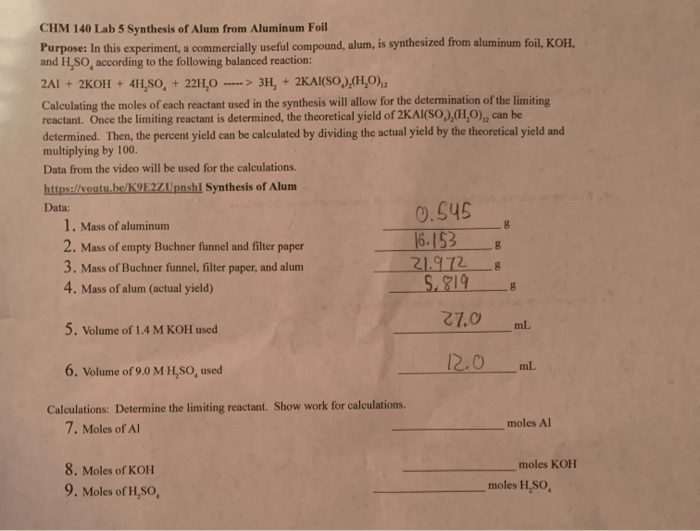

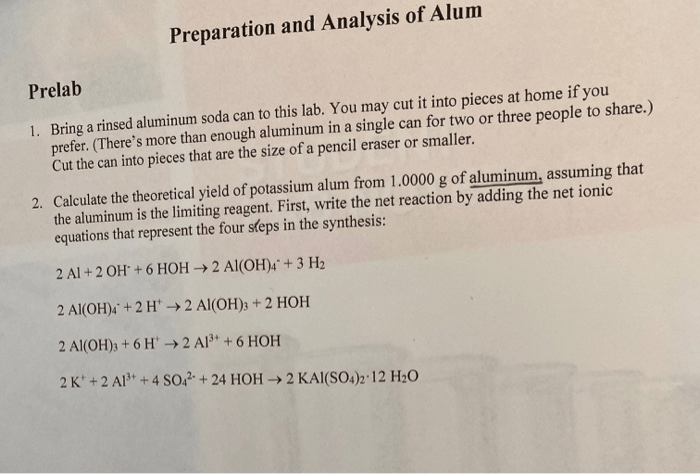

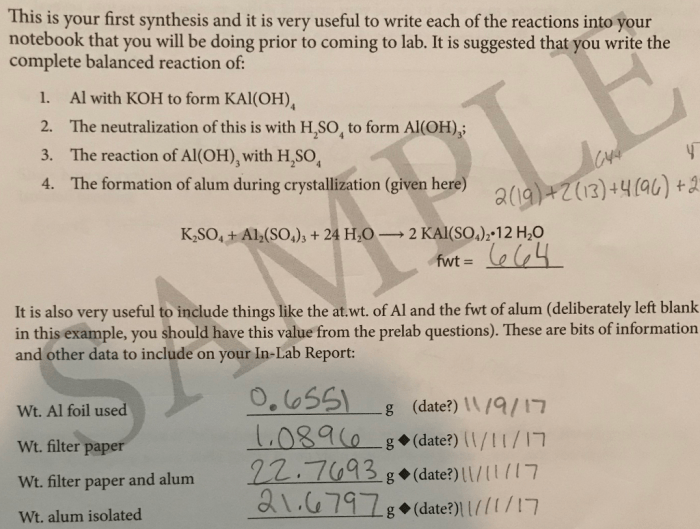

The chemical process of synthesizing alum can be summarized by the following equations:

- 2Al + 3H 2SO 4→ Al 2(SO 4) 3+ 3H 2

- Al 2(SO 4) 3+ K 2SO 4→ 2KAl(SO 4) 2·12H 2O (alum)

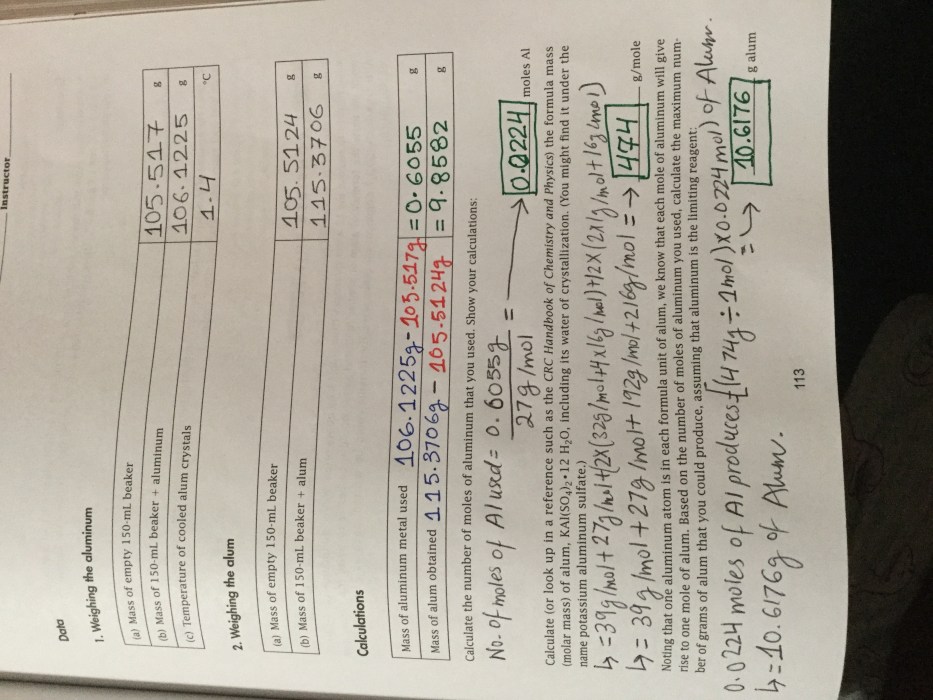

Step-by-Step Procedure

The following step-by-step procedure provides a detailed guide for synthesizing alum in a laboratory setting:

- Add 10 g of aluminum metal to a 250-mL beaker.

- Slowly add 100 mL of 1 M sulfuric acid to the beaker, while stirring constantly.

- Heat the mixture on a hot plate until the aluminum metal has completely dissolved.

- Filter the solution to remove any impurities.

- Add 20 g of potassium sulfate to the filtrate.

- Heat the solution until the potassium sulfate has completely dissolved.

- Allow the solution to cool slowly.

- As the solution cools, alum crystals will begin to form.

- Filter the crystals and wash them with cold water.

- Dry the crystals on a filter paper.

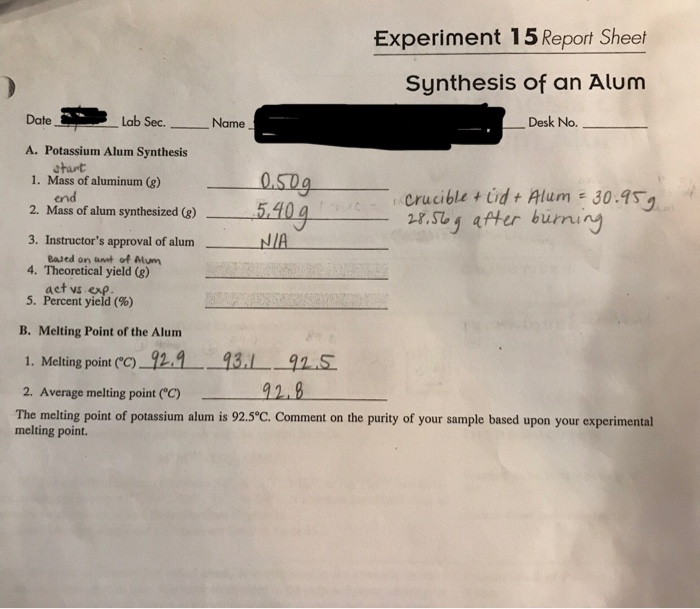

Properties of Alum

The following table compares the properties of alum before and after synthesis:

| Property | Before Synthesis | After Synthesis |

|---|---|---|

| Appearance | Aluminum metal | White crystals |

| Solubility | Insoluble in water | Soluble in water |

| Melting point | 660°C | 92.5°C |

| Boiling point | N/A | 200°C (decomposes) |

Applications of Alum

Alum has a wide range of applications in various industries and domestic settings.

Industrial Applications

- Paper industry:Alum is used as a coagulant in the production of paper, helping to bind the fibers together and improve the paper’s strength and quality.

- Textile industry:Alum is used as a mordant in dyeing processes, helping to fix dyes to fabrics and improve their colorfastness.

- Water treatment:Alum is commonly used as a coagulant in water treatment plants, removing impurities and suspended particles from water to make it safe for drinking or industrial use.

- Fire retardants:Alum is used in the production of fire retardants, helping to slow down the spread of fire and protect materials from burning.

Domestic Applications

- Baking:Alum is used as a leavening agent in baking, helping to create a light and fluffy texture in baked goods.

- Deodorants:Alum is used as an astringent in deodorants, helping to reduce sweating and body odor.

- Food preservation:Alum is used as a preservative in some food products, such as pickles and sauerkraut, to prevent spoilage and extend their shelf life.

Water Treatment, Synthesis of alum lab answers

Alum plays a crucial role in water treatment by removing impurities and suspended particles through a process called coagulation. Here’s how it works:

- Coagulation:Alum reacts with the impurities in water, forming positively charged aluminum hydroxide flocs.

- Floc formation:The flocs attract and entrap the suspended particles, forming larger and heavier aggregates.

- Sedimentation:The flocs settle down to the bottom of the water treatment tank due to gravity.

- Filtration:The clarified water is then filtered through a sand or gravel bed to remove any remaining impurities.

By effectively removing impurities, alum helps to improve the clarity, taste, and safety of drinking water, making it an essential component of water treatment processes worldwide.

Safety Considerations

Alum is generally considered safe to handle and use, but like any chemical, it is important to take appropriate safety precautions to minimize potential risks.

Potential hazards associated with alum include:

- Inhalation:Alum dust can irritate the respiratory system, causing coughing, wheezing, and shortness of breath.

- Skin and eye contact:Alum can cause skin and eye irritation, including redness, itching, and burning.

- Ingestion:Ingesting large amounts of alum can lead to nausea, vomiting, and diarrhea.

To ensure safe handling of alum, it is essential to follow these safety precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a dust mask when handling alum powder.

- Work in a well-ventilated area to minimize exposure to alum dust.

- Avoid direct contact with skin and eyes. If contact occurs, rinse the affected area thoroughly with water.

- Do not ingest alum. If ingested, seek medical attention immediately.

- Store alum in a cool, dry place, away from direct sunlight.

Safety Protocol for Handling Alum in a Laboratory Environment

To ensure the safe handling of alum in a laboratory environment, it is essential to establish a safety protocol that Artikels the following:

- Designated work area:Identify a specific area in the laboratory for handling alum, away from other activities.

- Proper storage:Store alum in a labeled container in a cool, dry place, away from direct sunlight.

- Personal protective equipment (PPE):Require all personnel handling alum to wear appropriate PPE, including gloves, eye protection, and a dust mask.

- Ventilation:Ensure adequate ventilation in the work area to minimize exposure to alum dust.

- Emergency procedures:Establish clear procedures for responding to spills, accidents, or other emergencies involving alum.

- Training:Provide training to all personnel handling alum on the potential hazards, safety precautions, and emergency procedures.

Environmental Impact

Alum production and use can have environmental implications that warrant consideration. Understanding these impacts is crucial for implementing sustainable practices and mitigating any adverse effects.

The extraction and processing of raw materials, such as bauxite and sulfuric acid, used in alum synthesis can disrupt ecosystems and generate waste. Additionally, the disposal of spent alum sludge poses challenges due to its potential to contaminate water bodies and soil.

Effects on Water Quality and Aquatic Ecosystems

Alum is widely employed as a coagulant in water treatment plants. While effective in removing impurities, its use can introduce aluminum into water bodies. Elevated aluminum levels can be toxic to aquatic organisms, particularly fish, as it disrupts their respiratory and osmoregulatory functions.

Excessive alum in water can also lead to eutrophication, a process where nutrient enrichment promotes excessive algal growth. This can deplete oxygen levels, harming aquatic life and disrupting the ecosystem’s balance.

Answers to Common Questions

What is the chemical formula of alum?

KAl(SO4)2·12H2O

What are the potential hazards of handling alum?

Alum can cause skin and eye irritation, and inhalation of dust can lead to respiratory problems.

How can I minimize the environmental impact of alum synthesis?

Use sustainable practices in waste disposal and minimize water consumption during the synthesis process.